ABOUT

It all started in 2017 when Roy Matheson planted around 3000 apple trees. The orchard lies on the south facing slopes of Kirkhill, just outside the town of Elgin in the North East of Scotland. The trees are protected from the wind by a birch wood. The apple trees are dwarf rootstock trees, they won’t grow much higher than they are now (about 5 feet). This height makes harvesting easier. During the year we take care of the trees and the soil. In January and February we prune the branches of the trees to maintain the height of the trees and give the apples space to grow…

We grow 14 different varieties, this helps to spread harvesting time. And together the apples mix well, the blend gives the juice it’s extraordinary variable taste.

During springtime, the orchard transforms into a sea of flowers. We have bee hives in the orchard, the bees work all day to pollinate the blossoms so the apples appear. Other bugs like spiders and ladybirds help to catch insects that can do harm to the trees…

In summer the applets appear, the trees release some of the applets so the ones that stay on the tree have space to grow into big apples.

During summer the apples grow and by the end of this season they ripen. They are checked daily to see if they are ready for harvesting. When the pips are dark brown the apples are ready to be picked.

When the first apples are ready, the harvest starts. The busiest time of the year. The apples are picked by hand so we need as many helpers as we can get. The orchard is fenced so badgers and deer can’t get access to the fields.

Only 100 yards from the orchard the apples are pressed and pasteurised in a trailer. This trailer contains everything we need to process the apples into apple juice.

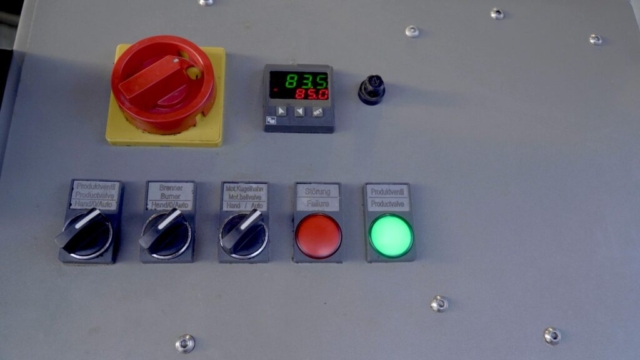

The apples are tipped on to the inspection table, then washed and pressed. The juice is transported to a holding tank, where it waits to be pasteurised. We flash pasteurise the juice at a minimum temperature of 83.5 degrees Celsius. If the temperature drops below this, the juice recirculates in the pasteuriser and when the right temperature is reached again the pasteuriser sends it to the bottling tank. This way, the juice is pasteurised in a safe manner and it extends the shelf life.

After pasteurising the juice is bottled, capped, allowed to cool down before labeling. Then they are ready to be transported to our retailers in Moray and beyond.